- Stock: In Stock

- Brand: KAISI

- Model: KAISI-138

- Weight: 0.04kg

(11AM - 6PM)

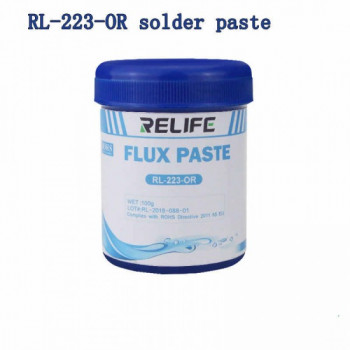

Solder tin paste is a new type of solder material that comes with SMT.

Solder paste is a complex system that is made of a paste of solder powder, flux, and other additives.

At the normal temperature, the solder tin paste has a certain viscosity, and the electronic component can be initially adhered to a predetermined position.

At the soldering temperature, the soldered component and the printed circuit pad are soldered together(Permanent connection.) with the evaporation of the solvent and some additives.

Instructions:

Before the opening, the temperature of the solder paste should be raised to the ambient temperature (25℃), and the temperature return time should be about 3-4 hours. It is forbidden to use other heaters to raise the temperature instantaneously.

After the solder paste is opened, it is recommended to use it within 24 hours at room temperature.

Placed in the air for a long time, the solder paste will become a tin block due to moisture absorption.

The indoor temperature should be controlled at 22-28 degC, and the humidity RH30-60% is the best working environment.

To wipe the wrong substrate, it is recommended to use industrial alcohol or industrial cleaner.

Preservation method:

The solder paste should be kept at 0-10℃.

The solder paste should be used for 12 months.

The solder paste should not be placed in the sun.

Precautions:

Use only with adequate Ventilation.

The solder paste contains organic solvent. Avoid repeated contact with skin. If the solder paste gets on your skin, wipe it off with alcohol and rinse thoroughly with water.

In order to be cautious, in the operation, the smoke released by the solvent during operation should be avoided as much as possible, and the skin and mucous membrane tissues should not be contacted for too long. Avoid repeated breathing of vapor.

Avoid contacting with eyes.

Keep away from children.